Vane Cell Damper

Mechanical purge valves for transport of hazardous liquids are opened with rods, which are operated by a lever on one of the two sides of the tank. Usually, the lever is rotated by 120°. The spring force of the purge valve acting in the closing direction requires a large torque to move the lever. The lever is locked in the end position. After the loading or unloading process, the purge valve must be closed again. For this action the locking of the lever has to be released and the entire reset torque is immediately applied to the hand lever. Depending on the size of the purge valve and the strength of the spring, a strong recoil occurs here, which has to be taken by the operator manually. This process can cause considerable injury to the operator, as well as damage to the valve seat and the bearings in the actuating rods.

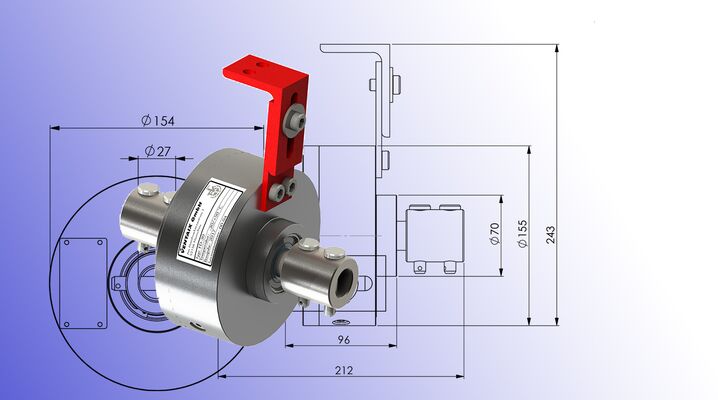

With the FD-30 vane damper, purge valves on tank wagons can be closed safely and in a controlled manner. As a special feature the vane damper is damping the closing movement only, while the actuation of the lever for opening is undamped. The damping is caused by the fluid in the vane damper. If the restoring torque is higher the damping of the rotary movement is proportionally higher and the hand lever moves smoothly to the start position. In this way the closing action of the mechanical purge valve loses its dangerous and harmful effect for both, the operator and the tank wagon closing device.

The installation of the vane damper is extremely simple and can be carried out on the existing actuating rods of any tank wagon. All that is required is to cut the existing handwheel shaft at a suitable position, remove a piece of the shaft and install the vane damper in the resulting gap using shaft adapters. With the adjustable mounting bracket, the vane cell damper is attached to the tank wagon at a suitable position.

In case of any further questions, please don’t hesitate to contact us

Contact us now!

Download

Vane Cell Damper FD 30

Datenblatt