Ventilation Valve

The equalization of pressure is essential for loading and unloading rail tank cars. There is a high risk for the operating personnel as well as for the environment and assets if tanks are not well ventilated (Example for non-vented tank). Therefore, ventilation valves are essential for ensuring the safety of tanks used for transporting and storing liquids. Their independent and reliable function is the key safety issue in any situation.

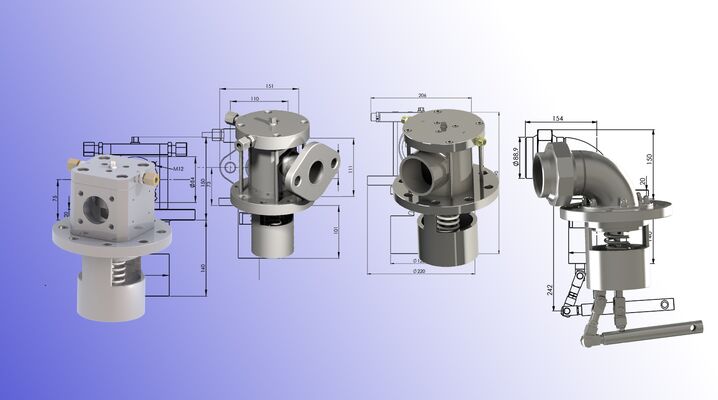

Series ZB2-100 forced ventilation valves are incorporated in the hydraulic circle of the loading and unloading process of the rail car tank. Regardless of weather and operating conditions, the valve opens reliably. The modular design of series ZB2-100 yields additional safety features. In case of an accident, the hydraulic drive of the valve can be damaged or even totally detached from the vessel without opening the valve and purging liquid to the environment.

Series ZB2-100 has the appropriate approval according to EN 14432:2014 and can be used on any approved rail tank car.

Contact us now!

Technical Data

| Type | ZB2-100 | ZB3-65 | ZB4-100 | ZB5-100 |

| Actuation | hydraulic | mechanical | ||

| Pressure Range |

PN 10 | PN 6 | PN 10 | PN 10 |

| Venting Ports |

2 x DN 50, Rectangular Flange | 1 x DN 40, Oval Flange | DN 80 | DN 80, Screw Connection |

| Length Beneth Top Of Tank |

140 mm | 100 mm | 140 mm | 140 mm |

| Length Above Top Of Tank | 150 mm | 150 mm | 150 mm | 150 mm |

| Flange | DN 100 | DN 65 | DN 100 | DN 100 |

| Hydraulic Port | DIN 2353 | - | ||

| Max. Hydr. Pressure | 12 MPa | - | ||

| Temperature | -20 °C bis +80 °C | |||

| Wetted Material |

1.0570 Zinc Plated, 1.4305, 1.4310, FPM (optional: 1.4571, Viton GF, PTFE) | |||

| Valve Seal |

PTFE (optional: Neoprène, Viton GF) | FPM (optional: Viton GF, PTFE) | PTFE (optional: Neoprène, Viton GF) | PTFE (optional: Neoprène, Viton GF) |

*Technical Modifications Withheld

Download

ZB2-100

Datasheet

ZB3-65

Datasheet

ZB5-100

Datasheet