Engineering services in industrial fluid flow technology

With over 30 years of experience, we deal with fluid dynamics challenges in industry. We offer comprehensive support in the development, project planning, and production of:

- Fluid dynamics equipment

- Fittings for the transport of hazardous materials

- Pump and filter systems for aggressive and corrosive liquids

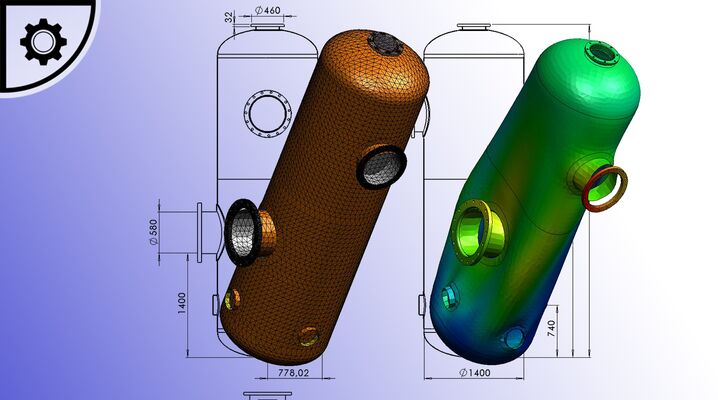

We place particular emphasis on the use of state-of-the-art design and simulation techniques. We perform precise FEM analyses (finite element method) on components and assemblies. These analyses enable us to make detailed predictions about the behavior of components under various loads and contribute to the optimization of designs and increased product reliability.

From idea to prototype: Holistic product development

We accompany our customers through the entire development process – from the initial idea to the realization and delivery of the finished prototype. This holistic approach includes:

- Concept development: Working closely with our customers, we generate innovative ideas and develop them into viable concepts.

- Design and construction: We translate the concepts into detailed 3D models and technical drawings.

- Simulation and analysis: We use simulation software to test the designs for functionality and performance.

- Prototyping: We use modern manufacturing technologies such as 3D printing to create prototypes quickly and cost-effectively.

- Deployment and optimization: The prototypes can be tested and validated in the field.

In this way, the end product not only meets the technical requirements, but is also optimally tailored to the needs of our customers.

If required, we can produce the components for series production and also assemble the developed products in our in-house workshop.